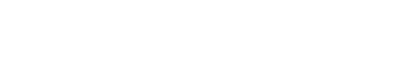

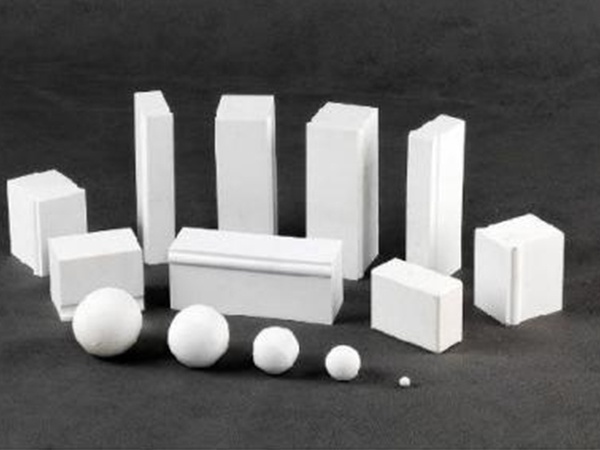

Ceramic Grinding Balls

Application:

The ceramic grinding balls is used as grinding media for ceramic body and glaze preparation, Thanks to the excellent wear resistance and hardness, it is suitable for both wet and dry grinding in both continuous ball mill and batch ball mill.

Performance Index:

|

Performance Product |

CPB92 |

CPB95 |

CPB92D |

CPB95D |

|

Al2O3(%) |

≥92 |

≥95 |

≥92 |

≥95 |

|

Moh’s hardness |

9 |

9 |

9 |

9 |

|

Rate of Water Absorption(%) |

≤0.01 |

≤0.01 |

≤0.01 |

≤0.01 |

|

Bulk Density (g/cm3) |

≥3.60 |

≥3.65 |

≥3.60 |

≥3.65 |

|

Self-Wearing Loss(%-24 hours) |

≤0.008 |

≤0.010 |

≤0.015 |

≤0.012 |

|

Application |

Wet grinding |

Wet grinding |

Dry grinding |

Dry grinding |

Remark: From 0.5mm up to dia.100mm are available.

Packaging:

25kg net in PP-bag or big bag of 500 or 1000kg net. 20-24MT/20' FCL.

Advantage:

Extremely cost effective

Improves grinding efficiency and energy costs

Longer service time due to low wear rate

Contamination-free to the color and composition of the ground material

Technical support provided to optimize milling conditions