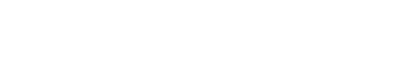

Ceramic Wear Liner

With its advantages of high wear resistance, corrosion resistance, long service life, high temperature resistance, impact resistance, environmental protection and energy saving, ceramic wear-resistant lining plates have performed well in the industrial field and become the first choice material for mass enterprises.

High wear resistance and corrosion resistance:

The ceramic wear-resistant lining plate is made of high-performance ceramic materials and has extremely high wear resistance. The wear resistance is 266 times higher than manganese steel and 171.5 times higher than high chromium cast iron1 . In addition, ceramic materials have good stability against a variety of chemical media, and can effectively prevent material leakage and pipeline corrosion, ensuring production safety1.

Long lifespan:

Because ceramic wear-resistant liners have excellent wear resistance and corrosion resistance, their service life is much longer than that of traditional metal pipes, usually up to decades2. This not only reduces the frequency of maintenance and replacement, but also reduces overall operating costs2.

High temperature resistance:

Ceramic wear-resistant lining plates can operate in high temperature environments for a long time, and can usually work stably in the temperature range of 0℃-250℃1. This characteristic makes it perform well in high-temperature environments such as high-temperature furnaces.

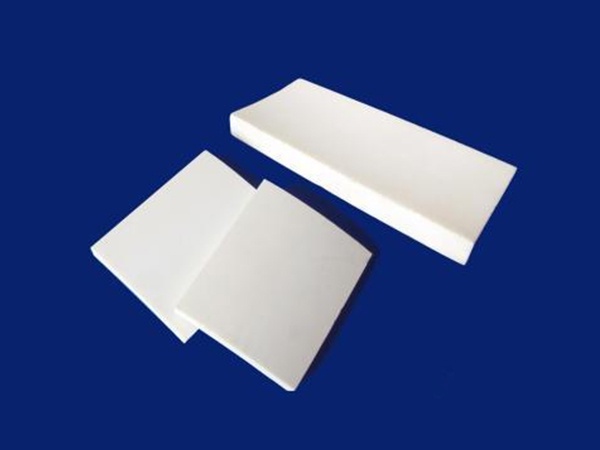

Impact resistance:

The toughened ceramic formula and unique spherical design enable the ceramic wear-resistant lining to resist the impact of large materials, ensuring that it can still maintain stable performance in harsh working environments.

Ceramic wear-resistant lining plates are widely used in coal handling, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other areas with heavy wear in enterprises such as thermal power, steel, smelting, machinery, coal, mining, chemicals, cement, ports and terminals. On mechanical equipment